-

Welcome to the Hydraulic Fracturing and Fracture Fluid Information Site. This website is a project of the BC Oil & Gas Commission and is intended to provide objective information on Hydraulic Fracturing. Fracturing Fluids, Groundwater and Surface water protection and related oil and gas activities in Canada.

-

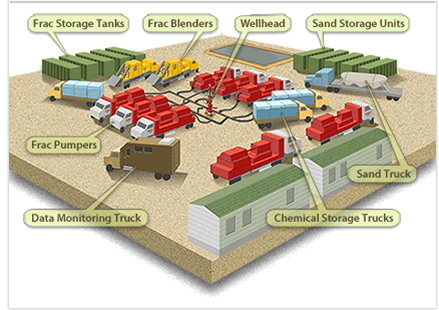

Hydraulic FracturingHow it WorksWell Site: Roads, trucks, a rig, pumping units and drilling equipment are all shuttled or stored at the drilling location.

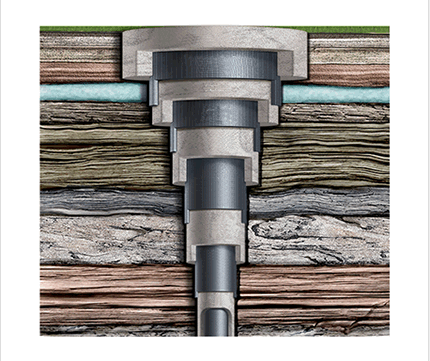

Casing:Layers of protective steel and cement are used to ensure water acqifers reamain undisturbed.

Casing:Layers of protective steel and cement are used to ensure water acqifers reamain undisturbed. Hydraulic Fracturing:Mixture of water, sand and chemicals pressurized and pumped into the well to form microscopic fractures in shale.This technique uses a specially blended liquid which is pumped into a well under extreme pressure causing cracks in rock formations underground. These cracks in the rock then allow oil and natural gas to flow, increasing resource production.

Hydraulic Fracturing:Mixture of water, sand and chemicals pressurized and pumped into the well to form microscopic fractures in shale.This technique uses a specially blended liquid which is pumped into a well under extreme pressure causing cracks in rock formations underground. These cracks in the rock then allow oil and natural gas to flow, increasing resource production.

More about the process > -

Casing & CementHow it WorksMultiple Layers: Layers of cement and steel are constructed between the producing wellbore and the water acquifer. This is a cross section showing the protective redundancy.Protective Depth: The first layer of casing typically runs 30-60 feet deep. The next layer runs 500-1,500 feet deep, with the inner most layer running 5,000-10,000 feet deep - thousands of feet below usable groundwater.Casing is the multiple layers of steel and cement inside the drilled hole used to protect water aquifers. The specific length, thickness, strength and composition of casing is regulated at the state level.

Learn More About Casing > -

ChemicalUse

Groundwater Protection: Priority Number One

Oil and natural gas producers have stringent requirements for how wells must be completed. The genesis of these requirements is water safety.

Casing is the first line of defense used to protect freshwater aquifers.

More About Groundwater Protection »

Chemical Use »

Chemical Use » How It Works »

How It Works » Regulations »

Regulations » News & Updates »

News & Updates » Ask a Question »

Ask a Question »