Hydraulic Fracturing - How It Works

Hydraulic Fracturing

How it Works

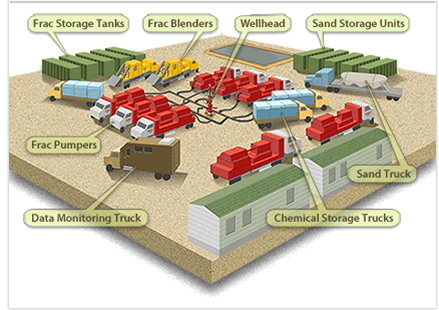

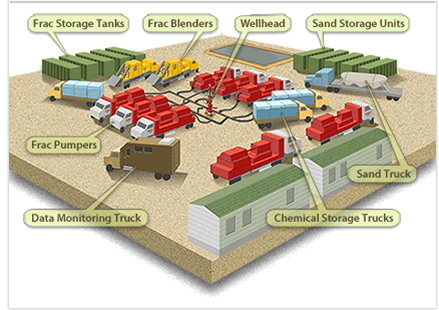

Well Site: Roads, trucks, a rig, pumping units and drilling equipment are all shuttled or stored at the drilling location.

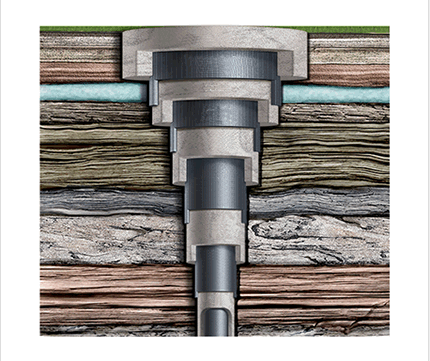

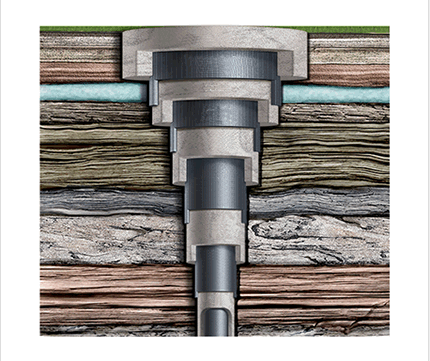

Casing:Layers of protective steel and cement are used to ensure water acqifers reamain undisturbed.

Hydraulic Fracturing:Mixture of water, sand and chemicals pressurized and pumped into the well to form microscopic fractures in shale.

This technique uses a specially blended liquid which is pumped into a well under extreme pressure causing cracks in rock formations underground. These cracks in the rock then allow oil and natural gas to flow, increasing resource production.

More about the process >